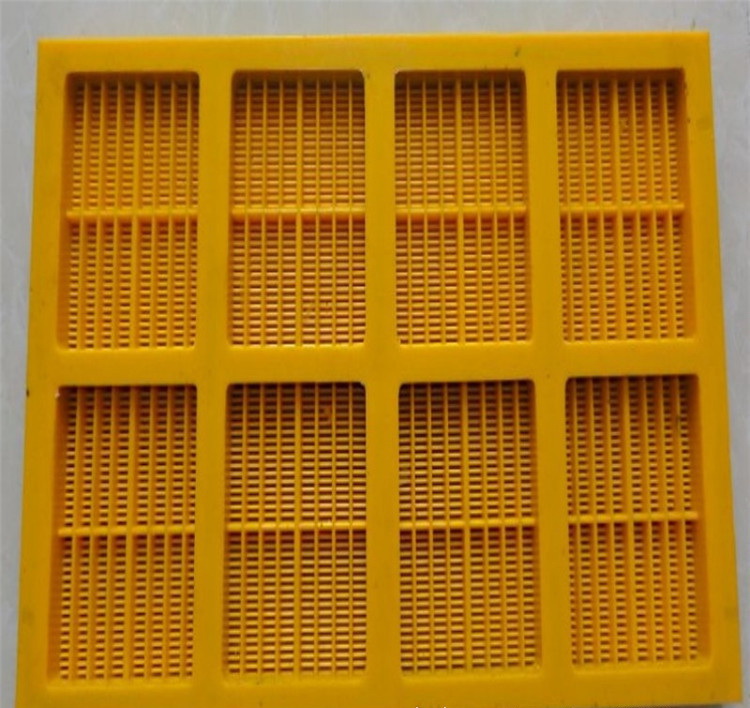

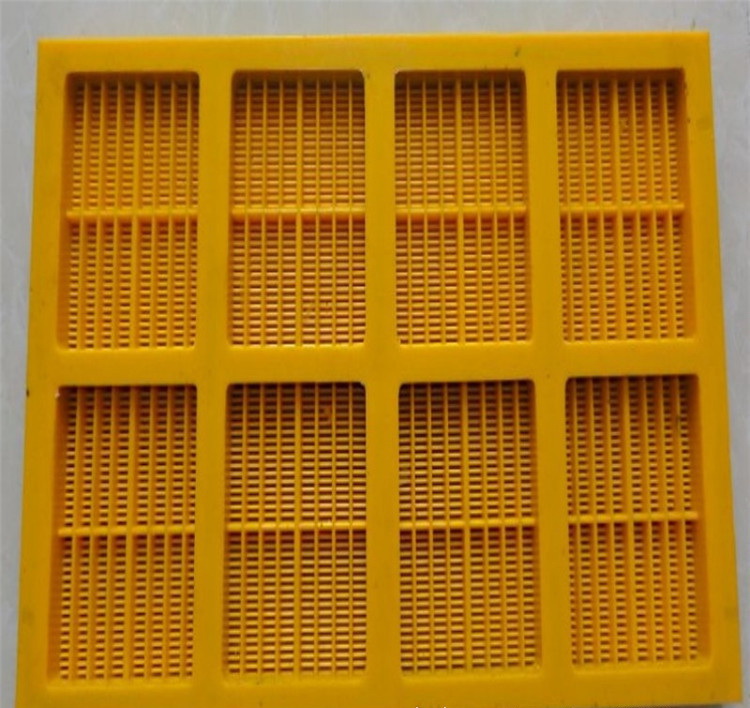

The Use and Characteristics of Polyurethane Screen

Polyurethane screens are suitable for screening materials of various properties, as well as materials that are wet and easy to clog, such as coal, coal gangue, coke, and slaked lime. It overcomes the screen sticking problem when various vibrating screens screen wet materials, and improves the output and reliability of the screening system.

1. Using the principle of rolling conveying, the friction coefficient is small, the wear is light, and the mesh is not easy to block.

2. The bracket adopts the overall shaft design, which works smoothly, without vibration and low noise.

3. Internal roller blind accessories are described separately, with simple planning and easy replacement and maintenance.

4. The roller body should be designed with a practical full sealing scheme, free from dust pollution.

5. Reliable operation, low-speed transmission, high transmission efficiency, low belt power, low energy consumption, and obvious energy-saving effect.

6. Different screen materials and screen hole standards can be selected according to customer requirements, with high screening efficiency, long service life and low maintenance cost.

The main performance and characteristics of polyurethane screen

1. Good wear resistance and long service life. Its wear resistance is 3 to 5 times that of steel sieve plates, and more than 5 times that of ordinary rubber sieve plates.

2. The maintenance workload is small, the polyurethane screen is not easy to damage, and has a long service life, which can greatly reduce the maintenance amount and downtime maintenance loss.

3. The total cost is low. Although the one-time investment of polyurethane screens of the same specification (area) is higher than that of stainless steel sieve plates (about 2 times), the total cost is not high, and the service life of polyurethane screens is 3 to 5 times that of stainless steel sieve plates. Less and more affordable.

4. It has good moisture resistance and can work under the condition of using water as the medium. In the presence of water, oil and other media, the friction coefficient between polyurethane and materials is reduced, which is more conducive to screening, improves screening efficiency, and avoids adhesion of wet particles. At the same time reduce the friction coefficient, reduce wear and prolong service life.

5. Corrosion-resistant, non-flammable, non-toxic and tasteless.

6. Due to the reasonable sieve hole design and the manufacturing process of the sieve plate, the particles of the limit size will not block the sieve hole.

7. It has good vibration damping performance and strong noise reduction ability, which can reduce noise and make the screen not easy to break during vibration.

8. Due to the secondary vibration characteristics of polyurethane, the polyurethane screen has a self-cleaning function, so the screening efficiency is high.

9. Energy saving and consumption reduction. Polyurethane has a small specific gravity and is much lighter than steel screens of the same size, thereby reducing the load on the screening machine, saving power consumption, and prolonging the service life of the screening machine.

Rubber Mold Plastic Mold Cold Isostatic Pressing Bags CIP bags