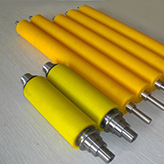

Polyurethane Roller

Polyurethane roller is a supporting component used in coating equipment. Using polyurethane as raw material, it is formed by melting and mixing of raw materials, synthesis of prepolymer, pretreatment of rubber roller casting mold, casting molding, vulcanization and turning and grinding. A colloidal material. The material is finely processed through different processes to form a rubber roller with a fine and smooth colloidal surface, and the colloidal material and the mandrel are firmly bonded. It has a good use effect with organic and inorganic material systems. It has the properties of bright surface color, stable size, good resilience and super viscosity.

High stain resistance: excellent two-way affinity surface, easy to clean stains, inert structure surface, not easy to pollute;

High physical properties: long-term use of the rubber roller will not harden and age, and the resilience performance is good.

Tear resistance: fine and smooth surface, one-piece structure.

High chemical resistance: good solvent resistance to toluene, alcohol and saline solution

High temperature resistance: adapt to high temperature and high humidity environment and cold and dry climate conditions in the north.

High usability: easy to store, can withstand high pressure, high speed, compression set, etc., long service life.

High wear resistance: The material has high strength and high tear resistance, so it has excellent shear resistance and wear resistance.

Range of use:

Fluorocarbon paint coating for thermal insulation decorative panels, furniture coating, steel and aluminum plate coating and other industries

1. Polyurethane rollers have excellent hydrophilicity and can be used as rubber rollers in dampening systems such as water and alcohol;

2. The surface adhesion of Polyurethane roller is strong, which can make the colloid material and the mantra bond firmly;

3. The hardness index of Polyurethane roller is very wide, which can adapt to different types of machines and meet the needs of different food;

4. Polyurethane rollers have good chemical properties and excellent physical properties, are not easy to age, will not harden, and have a long service life.

Polyurethane roller is a material made of polyurethane as raw material, and then finely processed through different processes. Its surface is bright, stable in size, and will not deform under high or low temperature conditions. In addition, it has super viscosity and is widely used in many industries and fields.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Rubber Mold Plastic Mold Cold Isostatic Pressing Bags CIP bags