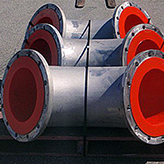

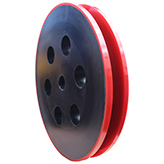

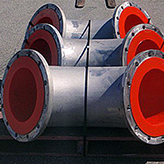

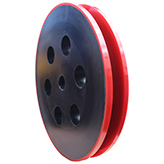

Polyurethane inner and outer lining products

tags: polyurethane lining, polyurethane liner, urethane liner, urethane lining, PU lining, PU liner

Polyurethane-lined rubber pipe has corrosion resistance, aging resistance, outstanding wear resistance and good elasticity. Its wear life is ten times that of steel pipe, and it overcomes the shortcomings of many wear-resistant lining pipes: cast stone lining weight Large, difficult to install and construct, high cost of pipeline installation and production; uneven thickness of ceramic lining, unstable quality, poor anti-wear ability; domestic rubber lining processing technology is not closed, once vulcanized pipeline is short. Corrosion resistance also has excellent anti-fouling, anti-scaling performance, unique casting process, 100% bonding of lining polyurethane elastomer and steel pipe, acid, alkali, radiation, hydrolysis and aging, small running aid Comprehensive performance characteristics such as high mechanical impact. Widely used in electric power, metallurgical mining, petrochemical, coal, building materials and other fields of wear-resistant, corrosion-resistant, anti-fouling pipeline delivery system.

Polyurethane products are widely used in national defense industry and mines because of their wear resistance, oil resistance, acid and alkali resistance, ozone resistance, aging resistance, low temperature resistance, tear resistance, impact resistance, high elasticity, strong vibration absorption capacity and large load support capacity. Machinery, construction machinery, chemical machinery, textile machinery, wood processing, printing machinery, metallurgical manufacturing, agricultural machinery and sports equipment.

The polyurethane-lined pipe is made of steel pipe as the base material, and is made of a rotating roller-coated polyurethane pipe anti-corrosion liquid (a special combination material for anti-corrosion in the pipe by a rotary roll coating method) as an inner lining material, which is compounded by an advanced process. Polyurethane lining pipe is processed and manufactured with special rotary roller coating frame. It adopts the process of integral casting and high-speed rotation once molding. It can be directly coated with polyurethane anti-corrosion coating on the inner wall of the pipe. The inner surface of the finished product is smooth like a mirror and no air bubbles. No seams, no lamination.

The rotary roll-coated polyurethane lining pipe process has the following characteristics:

1. No need for heating process, it can be cured at room temperature, and the curing cycle is short, which not only reduces energy consumption, but also improves delivery speed;

2, strong anti-wear performance, acid and alkali resistance;

3, the processing technology is simple, the equipment investment is small, the process flow is short, the production cycle adjustment is convenient, and the requirements for the production site are small;

4. The speed-adjusting roller coating process is adopted. After processing, the inner wall coating is uniform and the surface is smooth. It is particularly advantageous for tubes with excessive volume, long length and small aperture which are difficult to solve by traditional techniques;

5. Different hardness and performance can be adjusted at will, and the operation time and gel time can be adjusted according to the production environment.

Polyurethane-lined pipes have the following characteristics:

1. Good wear resistance. Because the lining polyurethane has good elasticity, when it is impacted by the medium, the polyurethane is forced to compress under the action of external force. After the external force disappears, the polyurethane is restored to its original state. This kind of “soft steel” is greatly reduced. The abrasion caused by the direct erosion of the inner wall of the pipe by the medium has a wear life of more than ten times that of the steel pipe.

2, anti-fouling The lining polyurethane elastomer has a symmetrical molecular structure, which is non-polar to the outside, and can not form the adsorption of Ca2+, Co32-, HCO3, OH ions in the slurry, and does not form a scale layer. It has a smooth inner surface and good elasticity, which can prevent the adhesion of the scale layer, so it has better anti-scaling and anti-scaling properties.

3. Low running resistance The surface of the inner lining is smooth and transparent, and the absolute roughness of the inner wall is 0.082, which can reduce the running cost.

4, good water stability, good aging resistance It will not swell in water like rubber products, affecting the performance.

5, combined with the inner lining polyurethane and steel pipe tightly combined, using a unique process, the cast polyurethane body and the steel pipe to achieve 100% combination, a unique overall flanging process, there will be no shedding, void and partial tearing phenomenon .

6, light weight, easy to install Because the base tube uses a thin-walled tube, the weight is relatively light, the installation time base connection method can be: flange connection, flexible pipe joint connection, welded connection.

Polyurethane lining pipe application field

Polyurethane-lined pipe is an ideal conveying pipe in the liquid-solid, gas-solid and two-phase flow transportation industry at home and abroad. The pipe is lining a certain thickness of polyurethane anti-corrosion and wear-resistant material on the inner surface of the metal pipe, so that it has the strength of the metal pipe and has excellent corrosion resistance and wear resistance. Polyurethane lining pipes are widely used in metallurgical mine process pipelines, tailings pipelines, coal mine washing, coal preparation plant process pipelines, coal gangue discharge pipelines, and long-distance finished coal slurry transportation. Ash removal pipelines for thermal power plants, chemical water plant process pipelines, desulfurization and dedusting pipelines, non-metallic mine process pipelines, and tailings pipelines, urban water supply and drainage buried pipelines, sewage treatment plant process pipelines, and chemical and petroleum cracking Various conveying pipes for corrosion protection and wear resistance.

|

PU lined

|

polyurethane lining

|

|

urethane lining

|

polyurethane liner

|

|

urethane liner

|

polyurethane coated

|

|

PU coating

|

PU liner

|

|

PU coating

|

polyurethane coating

|

Contact High Industry Tech

Tel: +86-15905285887 Mr. Bluce Yan

pu@highindustryco.com

Wechat/QQ ID: 15905285887

Skype ID: bluce_yan