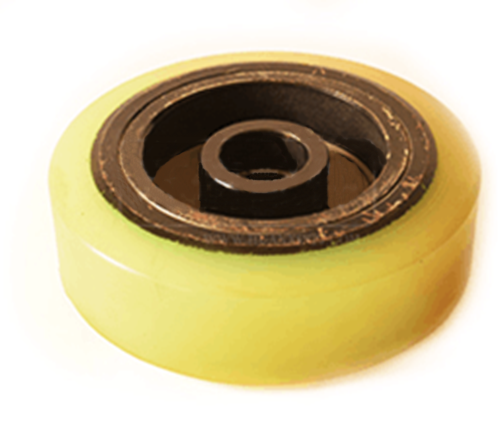

Polyurethane Fork Wheel

Categories: polyurethane forklift wheels

Application: Polyurethane Fork Wheel

InquiryMain description:

Polyurethane Fork Wheel

Polyurethane Fork Wheel

Polyurethane Fork Wheel

As one of the vulnerable parts of the forklift movement, the forklift wheel plays a very important role in the flexible, stable, safe and economical use of the forklift during driving. It is very important to improve the service life of tires, improve the working efficiency of forklifts and reduce operating costs. The characteristics of PU polyurethane forklift wheels are mainly good wear resistance, not easy to damage the ground (such as: epoxy floor, marble, ceramic tile, wooden floor, etc.), and the net weight is slightly heavier; Nylon wheels: inherently lighter, slightly louder, wear resistance General; rubber wheels: good sound insulation effect, soft material, more outlets.

In the maintenance of the fork wheel, we need to know that first of all, find a manual forklift or jack to lift the whole forklift, and then use wood lining to fix it. Securely attach the forklift wheel to the underside of the pedal, making sure the screw holes are in the correct location. Tap it into and screw on the Linda forklift wheel mounting plate, making sure the screws are tight. Install the wheel on the other side in the same way. After installation, check whether there is shaking and adjust in time.

The main function of the fork wheel pattern is to increase the friction between the tread and the road surface to prevent the wheel from slipping. The sample pattern will cause a large tangential elastic deformation under the action of force. As tangential force increases, tangential deformation increases and so does the "friction" of the contact surfaces, preventing the tendency of the tread and road surface to slip or slip. The forklift wheels have reached the above limit and may burst or be dangerous. It must be replaced with a new one to ensure safe operation. The wear limit in use is: the remaining groove depth of the engineering machinery tire (about 1/4 of the tread width) is 15% of the groove depth of the new tire; when the tire has uneven wear, staggered wear or other abnormal During normal wear; areas exposed. Work limitations for injuries are; Trauma extended to core wire or core wire broken; Core wire cut or loose; Forklift tire peeled off (separated); Gas or unusual repairs. When changing tires, professional forklift maintenance is required to avoid unnecessary damage.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Rubber Mold Plastic Mold Cold Isostatic Pressing Bags CIP bags