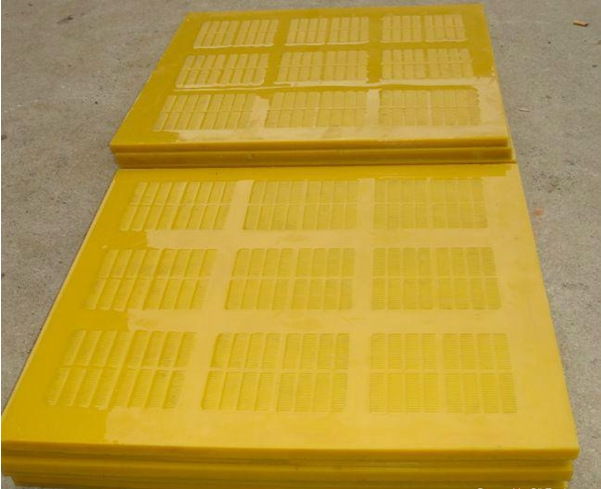

The Advantages of Polyurethane Mine Screen

Categories: Custom mould Polyurethane parts

Application: The Advantages of Polyurethane Mine Screen

InquiryMain description:

The Advantages of Polyurethane Mine Screen

The Advantages of Polyurethane Mine Screen

The Advantages of Polyurethane Mine Screen

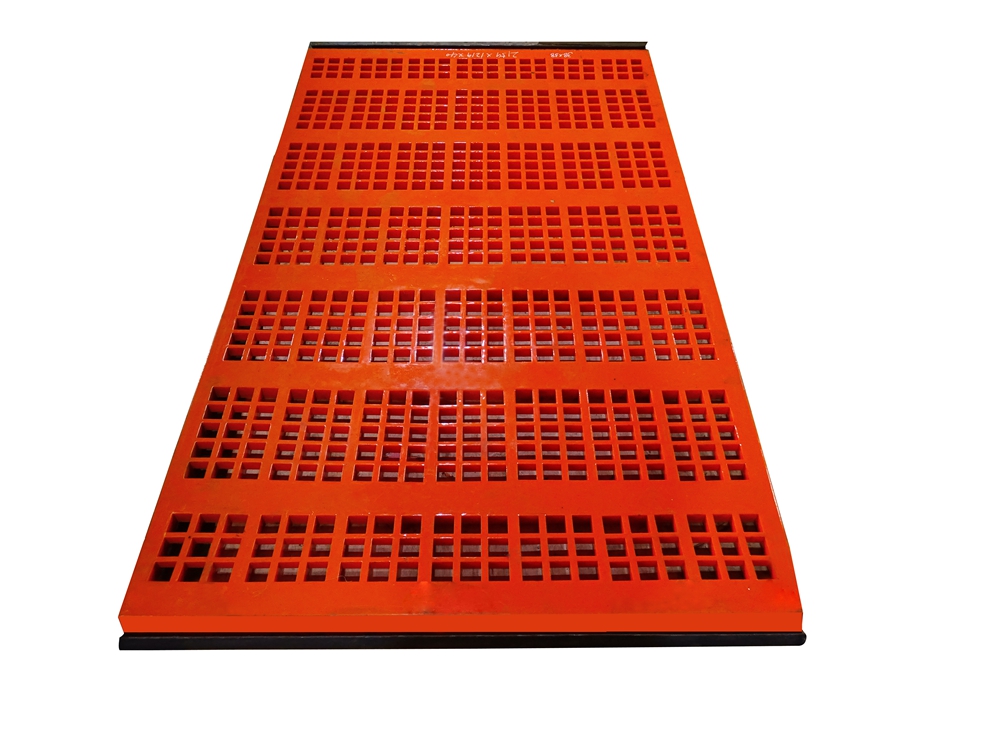

1. Long service life

The polyurethane elastic sieve plate adopts steel rope as the skeleton materials, coupled with the fact that polyurethane itself has a high elastic modulus, high strength absorption impact and high wear resistance, so it has a high tensile strength, whose carrying capacity is more than 2.5 times that of rubber sieve plate. Its service lifetime is 8-10 times higher than that of an ordinary metal sieve plate, 3 times that of heavy duty stainless steel screen and 3.9 times that of natural rubber, which is now the most wear-resistant screen material in the world. The product material of the polyurethane screen is a polymer organic elastomer, which has excellent wear resistance, flex resistance and carrying capacity. The production raw materials are specially treated to ensure that they won’t delaminate under long-term alternating loads.

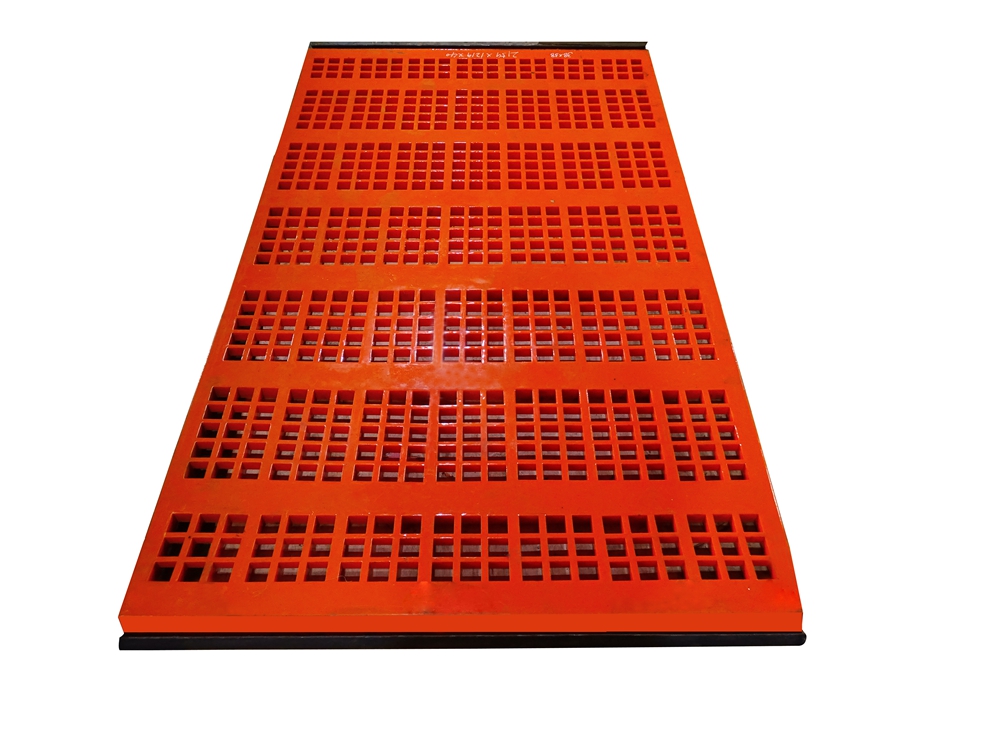

2. High screening efficiency.

The internal side of the sieve plate has self-cleaning performance with high screening efficiency while not blocking holes. Due to the strong water permeability of polyurethane screen mesh and the large cone angle of the sieve hole (140°), it can effectively prevent the adhesion of wet fine particles. Thus it fits for screening and grading wet fine particles and materials. Anpeng polyurethane screen adopts imported raw materials, and its elastomer and its own good tension performance can help effectively avoid blocking holes under dynamic conditions.

3. Wide scope of application.

Polyurethane screens are professionally applied in hydropower stations, building materials and other metal beneficiation industries. The screening of various materials in the range of 0.1mm-170mm, whether dry sieve or wet sieve, does not affect the screening efficiency. Dehydration and deselection in the range of 0.5m-3mm, more fully show the superiority of polyurethane screen surface. The product is water-resistant, corrosion-resistant, aging-resistant, easy to replace and maintain. Polyurethane mesh density is small (1.32kg/m3), lighter than metal screen surface, can reduce production unit consumption, so it can adapt to the large-scale development requirements of the sieve machines.

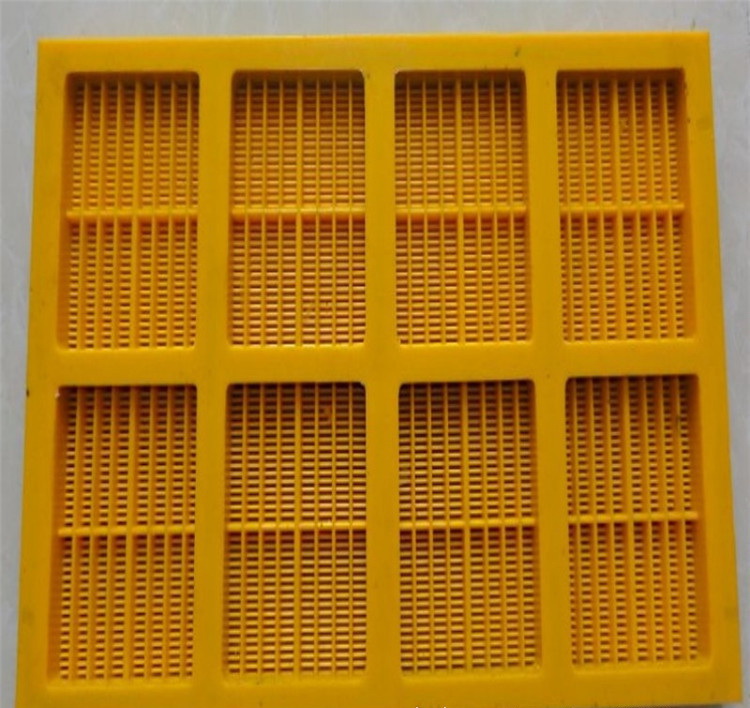

4. High screening accuracy

The production craftwork of polyurethane screen adopts the method of mold casting molding with accurate pore size and high screening quality, and the particle size of the material screened from it can greatly meet the users' requirements. With simple installation and is easy to replace and overhaul, the product made by our wire mesh screen company fits for any type of screening machine, and the workload of on-the-spot installation, replacement or maintenance is largely reduced due to its lightweight.