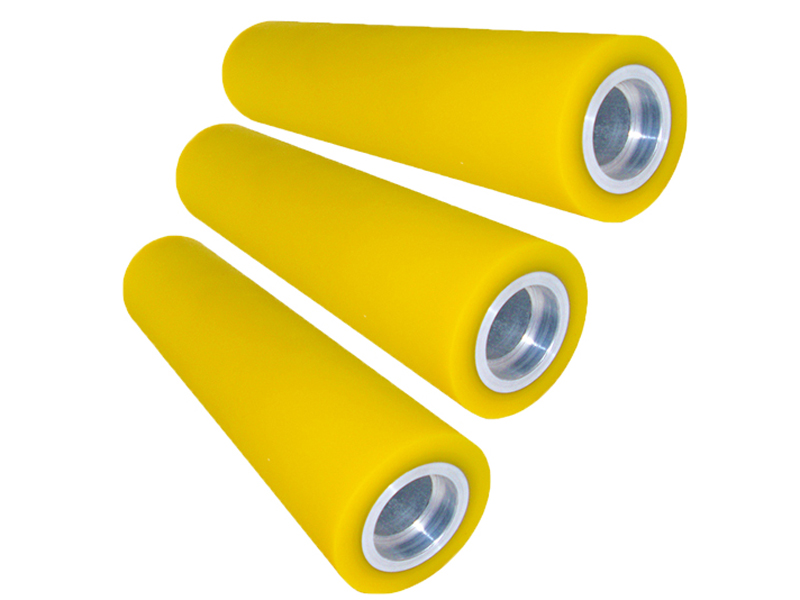

Polyurethane Roller

Categories: PU coated rollers

Application: Polyurethane Roller

InquiryMain description:

Polyurethane Roller

Polyurethane Roller

Polyurethane Roller

Polyurethane roller is a kind of high performance roller, which is widely used in printing, coating, composite, hot stamping, embossing, embossing, calender, indentation and other industries. The emergence of polyurethane rubber rolls has greatly improved production efficiency and product quality, and has become an indispensable part of modern industrial production.

Polyurethane roller is a roller made of polyurethane material, which has the characteristics of high elasticity, high wear resistance, high corrosion resistance, high temperature resistance, high adhesion and so on. The manufacturing process of polyurethane roller is very complex and needs to go through multiple processes, including raw material screening, mixing, heating, pressing, vulcanization and so on. The manufacturing process of polyurethane rubber rolls has a crucial influence on the quality and performance of the product.

Production technology of polyurethane roller

The production process of polyurethane rubber rolls is very complex and needs to go through multiple processes, including raw material screening, mixing, heating, pressing, vulcanization, etc. The specific production process is as follows:

1. Screening of raw materials

The manufacture of polyurethane roller requires the use of a variety of raw materials, including polyurethane materials, hardeners, fillers, lubricants and so on. In the production process, these raw materials need to be screened to ensure that their quality and performance meet the requirements.

2. Mixing of raw materials

The selected raw materials are mixed together in a certain proportion to form a raw material mixture of polyurethane rollers. In the process of mixing, it is necessary to control the mixing time and temperature to ensure uniform mixing.

3. Heating of raw materials

The raw material mixture is heated to a certain temperature so that it becomes soft and viscous. In the process of heating, it is necessary to control the temperature and time to ensure the performance and quality of the raw material mixture.

4. The pressing of raw materials

The heated raw material mixture is pressed into the mold to form the initial shape of the polyurethane roller. In the process of pressing, it is necessary to control the pressure and time to ensure that the shape and size of the polyurethane roller meet the requirements.

5. Vulcanization of polyurethane roller

The initial form of polyurethane roller is vulcanized in the vulcanization furnace to make it harder and more wear-resistant. In the process of vulcanization, it is necessary to control the temperature and time to ensure the performance and quality of the polyurethane roller.

Polyurethane roller is a kind of high performance roller, with high elasticity, high wear resistance, high corrosion resistance, high temperature resistance, high adhesion and so on. Polyurethane rubber rolls are widely used in printing, coating, composite, hot stamping, embossing, embossing, calender, indentation and other industries. The manufacturing process of polyurethane roller is very complex and needs to go through multiple processes, including raw material screening, mixing, heating, pressing, vulcanization and so on. The manufacturing process of polyurethane rubber rolls has a crucial influence on the quality and performance of the product.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Rubber Mold Plastic Mold Cold Isostatic Pressing Bags CIP bags