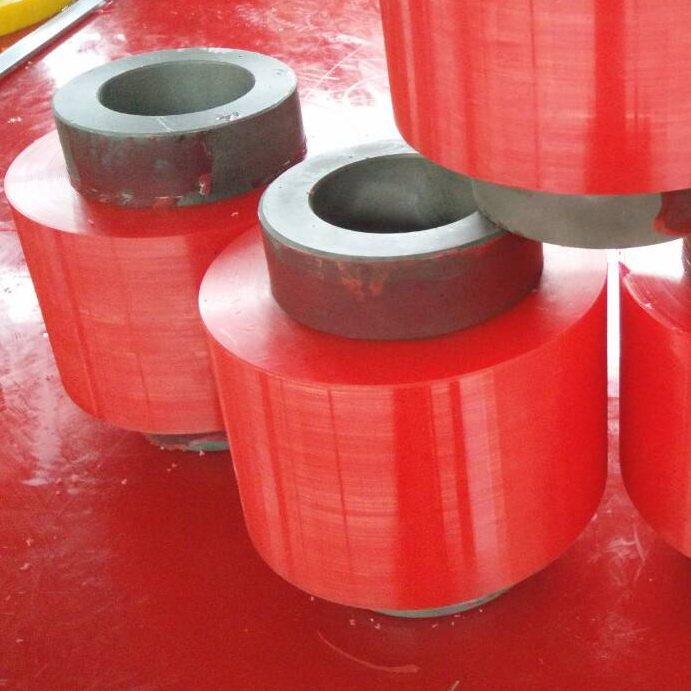

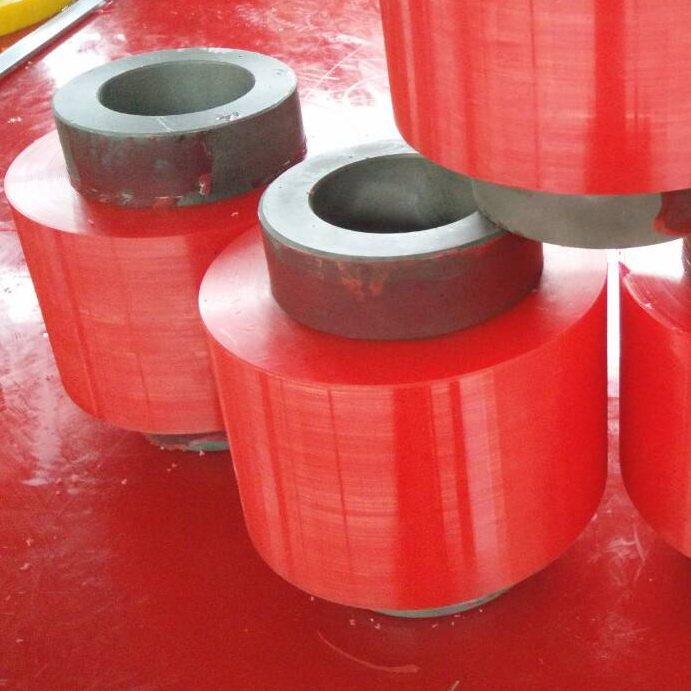

Why choose polyurethane as the material for heavy-duty and lagged rollers?

1. The bearing capacity of polyurethane wheels. Another advantage of polyurethane wheels for industrial applications is the material's coefficient of friction, a value that describes the ratio of friction between two objects to the force pressing them together. Rougher surfaces tend to have higher effective values because they create friction when squeezed together. Polyurethane lagged wheels tend to be a grippy material, so their high coefficient of friction helps keep the trailer from tipping over. For hard wheel materials, slippage can be an important consideration. Urethane also provides traction to the drive wheels and helps reduce the load on the rollers to achieve the desired drive.

2. Heavy-duty driving wheels coated with polyurethane can protect the ground. Urethane rollers are ideal for floor protection applications as they deflect and take up more floor space than hard wheel materials such as nylon. The larger surface area helps reduce stress concentrations on floors and keeps them in shape for longer.

3. The corrosion resistance of polyurethane coated rubber rollers in special fields. There are many different types of polyurethane rollers with varying degrees of resistance to certain environments or conditions. For example, chemicals, solvents and even water, some polyurethane rollers will not break down or corrode in the presence of water in wet or wet environments. When chemical exposure is an issue, different types of polyurethane can be used to extend the life of the rollers.

4. Polyurethane rollers are used for industrial rubber wheels to reduce noise. Urethane rubber-coated wheels are preferred in industrial applications due to their quiet operation compared to hard wheels such as steel or cast iron. The urethane acts as a shock absorber, helping to cushion the ride and absorb bumps from uneven terrain. Using polyurethane instead of steel or cast iron wheels can greatly reduce noise levels and help protect employees' hearing.

5. The bearing capacity of polyurethane roller is higher. Compared with polyurethane rubber, polyurethane rollers are commonly used because of their load carrying capacity. Polyurethane rollers can provide greater load capacity while still providing the benefits of rubber treads such as noise reduction, shock absorption and floor protection.

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com

Rubber Mold Plastic Mold Cold Isostatic Pressing Bags CIP bags