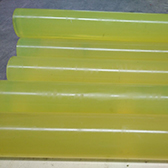

Polyurethane rod

What are the advantages of Polyurethane Rod?

Very good abrasion resistant

Oil and solvent resistant

Deformation resistance

Resistance to ageing

Tear resistant

Excellent noise abatement properties

Excellent vibration abatement properties

What features does Polyurethane Rod have commerically?

Excellent abrasion resistance

Outstanding low-temperature performance

Excellent mechanical properties, combined with a rubber-like elasticity

High shear strength

High elasticity

High resistance to sunlight and weather conditions

What Polyurethane Rod is used for?

Applications include automotive suspension bushings, gaskets, seals, castors, wheels, bearing seals, valve inserts, shock absorbers, noise dampers as well as roller coaster and escalator wheels. It is also used as a wear strip on snow ploughs as well as pulleys on fishing trawlers.

Is there a summary for Polyurethane Rod?

Polyurethane rod is a thermo set plastic that, when formed, tends to retain its shape, flexibility and resilience under stress, tension or compression. With the ability to be formed into practically any shape, size, and hardness, polyurethane is extremely versatile. It has better abrasion, ageing and tear resistance than rubber, while offering higher load bearing capacity without the deformation issues. Compared to other plastics, polyurethane offers superior impact resistance, while offering excellent wear properties and elastic memory.