Applications of Polyurethane Elastomers

1. Application in coal preparation, mining, metallurgy and other industries

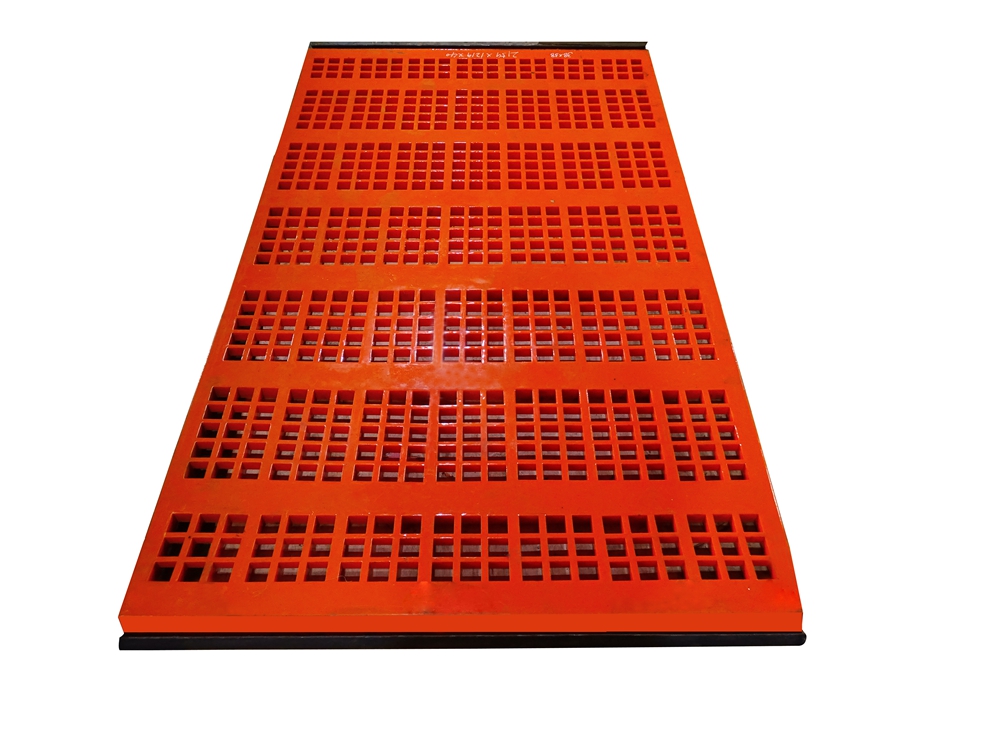

Polyurethane elastomer is the non-metallic material that most meets the requirements of mines and can replace some metal materials. Polyurethane elastomer products used in mines include sieve plates, elastomer linings, conveyor belts, etc. The types of polyurethane rubber sieve plates include tension sieve plates, tension sieve plates, slotted sieve plates, etc. Polyurethane rubber sieve plate has excellent characteristics of wear resistance, water resistance, oil resistance, vibration absorption and noise reduction, high strength, and strong bonding with metal frame, low noise, good self-cleaning effect, and reduces the load of the screen machine, saves energy consumption and prolongs the life of the screen. The life of the sieve machine is long and the quality of the sieve is high.

Many mining equipment, such as shaking table, flotation machine, special concentrator, family flow device, spiral trough, pulverizer, magnetic separator, pipes and elbows, contact with gravel and other materials, need wear-resistant lining; mining monorail Polyurethane elastomer is the preferred material for steel core polyurethane drive wheels of cranes, flame retardant and antistatic polyurethane conveyor belts, equipment cable TPU sheaths, dust seals, shock absorbers, etc.

2. Polyurethane roller application

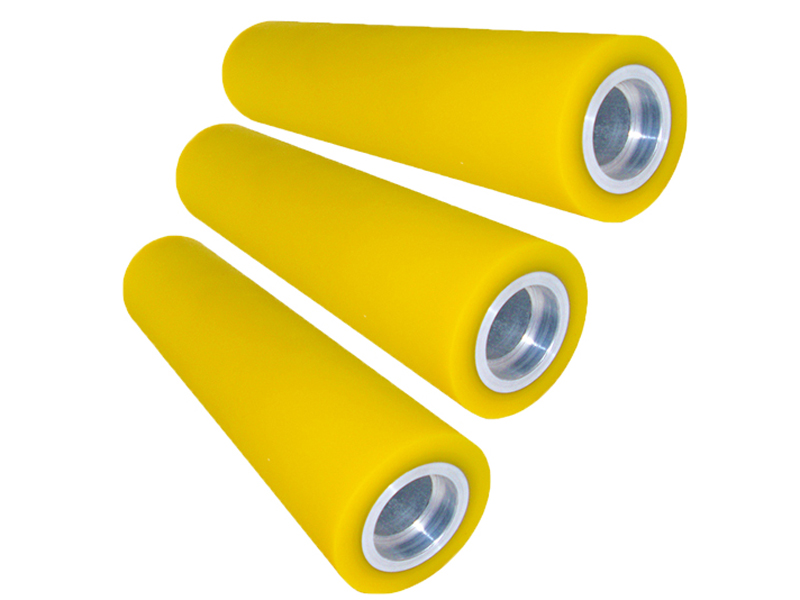

Polyurethane rubber roller is a kind of polyurethane rubber product with excellent performance. It is generally made of steel or iron roller covered with a layer of polyurethane elastomer by casting process. According to the use, there are: hulling rubber rollers for grain processing, extrusion rubber rollers and pulping rubber rollers in the paper industry, drawing rollers, drafting rollers and shredding rollers in the textile industry, wood, glass and packaging Cots for transmission bearings used in industry, various cots for printing and dyeing machinery, small cots for various instruments, transmission cots for conveying systems, printing cots, transmission cots for metal cold rolling, color-coated cots for metal steel plates, etc. etc., the rubber layer of these rubber rollers can be made of polyurethane elastomer.

Most of the rubber rollers are manufactured by pouring process, generally by placing the steel core in the center of the cylindrical mold and pouring the elastic body. The special rubber roller can adopt centrifugal casting method or rotary casting method. The spin casting method does not require molds and uses room temperature vulcanization to cast the elastomer system, reducing the total processing time.

3. Polyurethane rubber wheels and tires

Polyurethane elastomer has a large load-bearing capacity, wear resistance, oil resistance, and is firmly bonded to the metal skeleton. It can be used to manufacture rubber wheels widely used in various transmission mechanisms, such as; supporting wheels, guide wheels for production line conveyor belts, pulleys for cable cars, etc. . In terms of sports and entertainment, the wheels of high-end roller skates and scooters are made of polyurethane. Polyurethane rubber wheels also have the characteristics of oil resistance, good toughness, and strong adhesion. They are very effective in mining monorail cranes, rack cars and cleaning vehicles. Polyurethane is also used in small electronic and precision instrument transmission wheels, various universal wheels, etc.

There are also micro-foamed tires, PU foam-filled tires, etc.

4. Mechanical parts

Various sealing rings, shock absorbers, couplings, automobile anti-skid chains, etc.

5. Mold linings and blanking templates for forming sheet metal parts, etc.

When punching thin sheet parts with conventional steel dies, the fracture often has burrs. The stamping technology of replacing traditional steel molds with polyurethane rubber is a leap forward in sheet metal stamping technology, which can greatly shorten the mold manufacturing cycle, prolong the service life of molds, reduce the production cost of molded parts, and improve the surface quality and dimensional accuracy of parts. It is especially suitable for It is suitable for the trial production of small and medium batches and single-piece products, and is more suitable for thin and complex stamping parts.

In ceramic tile and ceramic production lines, the use of PU elastomer lining molds can reduce production costs, improve production efficiency and yield. Polyurethane can be used to manufacture concrete moulds. Urethane molds can be used to reproduce various patterns and produce decorative blocks. In the stamping production of metal molds, polyurethane elastomer rods, tubes and plate pads are used as cushioning components instead of metal springs. They have high elasticity, flexibility, and The original shrinkage deformation strength is high, and the mold will not be damaged.

Rubber Mold Plastic Mold Cold Isostatic Pressing Bags CIP bags